Ball Valve | Series M1

Ball Valve | Series M1

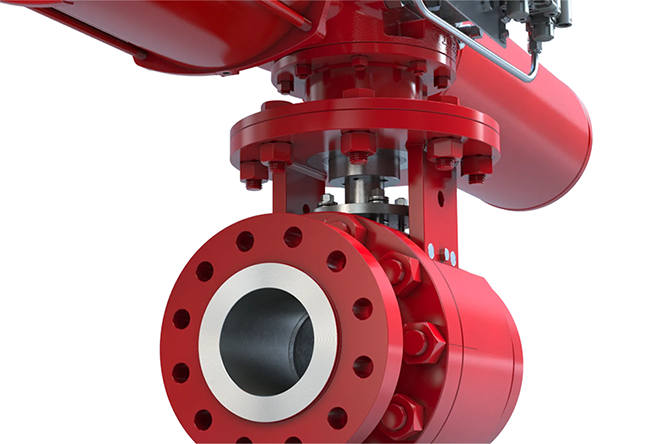

Industry-Leading Metal-Seated Valves for Power and Mining Sectors

Bray Series M1 Severe Service Metal Seated ball valves deliver exceptional performance and reliability in the most challenging flow control conditions. Series M1 Severe Service isolation valves are used in high temperature, high pressure, corrosive and erosive duty, critical duty and lethal service applications in power, minerals & mining, oil & gas, refining, chemical / petrochemical, agrichemical and specialty industries where absolute safety and reliability is demanded.

Series M1 Severe Service Ball valves are technically superior, featuring a heavy-duty drivetrain, 360° Mate-Lapped ball and seat, live load packings, heavy duty ISO 5211 actuator mounting, an innovative stem alignment method that eliminates stem side loads and ensures long packing life as well as propriety thermal spray coatings technology including HVOF or High Velocity Oxygen Fueled, APS or Atmospheric Plasma Spray, Plasma Transfer Arc PTA, Laser Cladding and other metalized coatings for extended service life in harsh conditions, minimizing downtime.

Series M1 valves are application specific, engineered and manufactured to order, with careful consideration of the process conditions required for your industrial flow control process. Our engineering and process application team are industry leaders with expertise in designing metal seated ball valves and will closely analyze your flow conditions and process chemistry including; temperature, pressure, thermal shock risk, abrasive erosion, corrosion, cavitation, flashing, solids handling and flow velocity in order to select the appropriate materials of construction and valve trim.

As a leading ball valve manufacturer, with 400 locations globally, Bray™ is dedicated to delivering value to our customers with high-performance severe service ball valves designed and manufactured with the highest quality and craftsmanship in the industry.

|

Size Range: |

NPS ½ to 36 / DN 15 to DN 900 Larger Sizes Available upon request |

|

Temperature Range: |

Up to 1100°F (593 °C) (Higher temperatures consult factory) |

|

Maximum Allowable Operating Pressure: |

ASME Class 150 to 4500, EN 1092 PN10 to 720 (Higher pressures consult factory) |

|

Ball Materials: |

Standard: 410 Stainless Steel, 316 Stainless Steel Optional: Inconel, Incoloys, Titanium, Duplex Stainless Steel, 17-4 PH Stainless Steel |

|

Design Standard : |

ASME B16.34, API 608, PED ASME Section VIII - Div 1, Appendix 2 |

|

Testing Standard: |

MSS SP61, API 598, ANSI/FCI 70-2, ISO 15848-2 |

|

Ports |

Full port, Standard Port, Reduced Port, Special ports available |

|

Fugitive Emissions Standard |

API 641, ISO 15848-1 |

|

Body Materials: |

Standard Forged: A105 Carbon Steel, A182 F3 Austenitic Stainless Steel, A182 F9 Alloy Steel Standard Cast: A216 Gr WCB, A351 GR CF8M, A217 Gr C12 Alloy Steel |

|

Stem Materials: |

Standard: A638 Gr 660 Optional: Inconel, Incoloys, Titanium, 17-4 PH Stainless Steel, Duplex Stainless Steel |

|

Seat Materials: |

Standard: 410 Stainless Steel, 316 Stainless Steel Optional: Inconel, Incoloys, Titanium, Duplex Stainless Steel, 17-4 PH Stainless Steel |

|

Body Style: |

Split Body (Two piece and Three piece) |

|

End Connections: |

Raised Face Flange (ASME B16.5, EN 1092-1) Ring Type Joint (ASME B16.5) Butt Weld (ASME B16.25) Socket Weld Grayloc® |

|

Certifications: |

API 607, API 641, CRN, ISO 15848-1, ISO 15848-2, PED, PE(S)R, TR CU |

|

Face to Face: |

ASME B16.10 (long pattern as standard), EN 558-1 |

|

applications: |

Power, Oil & Gas, Refining, Petrochemical, Synfuels, Mining Autoclaves, Slurry Transport, Aerospace, Steel, Pulp & Paper |

Head Office

31, av. Luapula, Q/Joli Site Aeroport – C/Manika | Kolwezi | Lualaba | DRC

Call Us

(+243) 855 855 605